After a shortage of PVC, fewer colours available for colour vinyl, supply chain issues with paper and card, delivery prices rocketing and increasing energy charges, the next in the long line of misfortunes to hit the vinyl record industry is a shortage of Nickel.

Recent headlines displayed -

The chaos at the London Metal Exchange that saw the nickel market suspended for a week has had at least one unusual side effect – the £100 million vinyl record industry is in turmoil.

The price of nickel doubled to more than $100,000 a tonne in just hours. Trading was suspended and the nickel crisis caused more turmoil in what was a resurgent industry.

The vinyl plants we use source nickel from Canada, but many other industries source via routes that are affected by current events in Ukraine. With those routes now struggling to access nickel, it has put a strain on the overall availability of nickel.

It’s true that one or two vinyl plants have suspended new orders and others are reviewing policies of making duplicate stampers or making 2 step or 3 step stampers. 3 step was often referred to as a full family, as the master was called a father, the positive the mother and the stampers the children. 2 step mastering just produces the children and only around 1000 records can be pressed in this way. 3 step electroplating (see below) creates a family where more stampers (children) can be grown from the mother.

So what is Nickel used for and why is it so important in the process of making vinyl records?

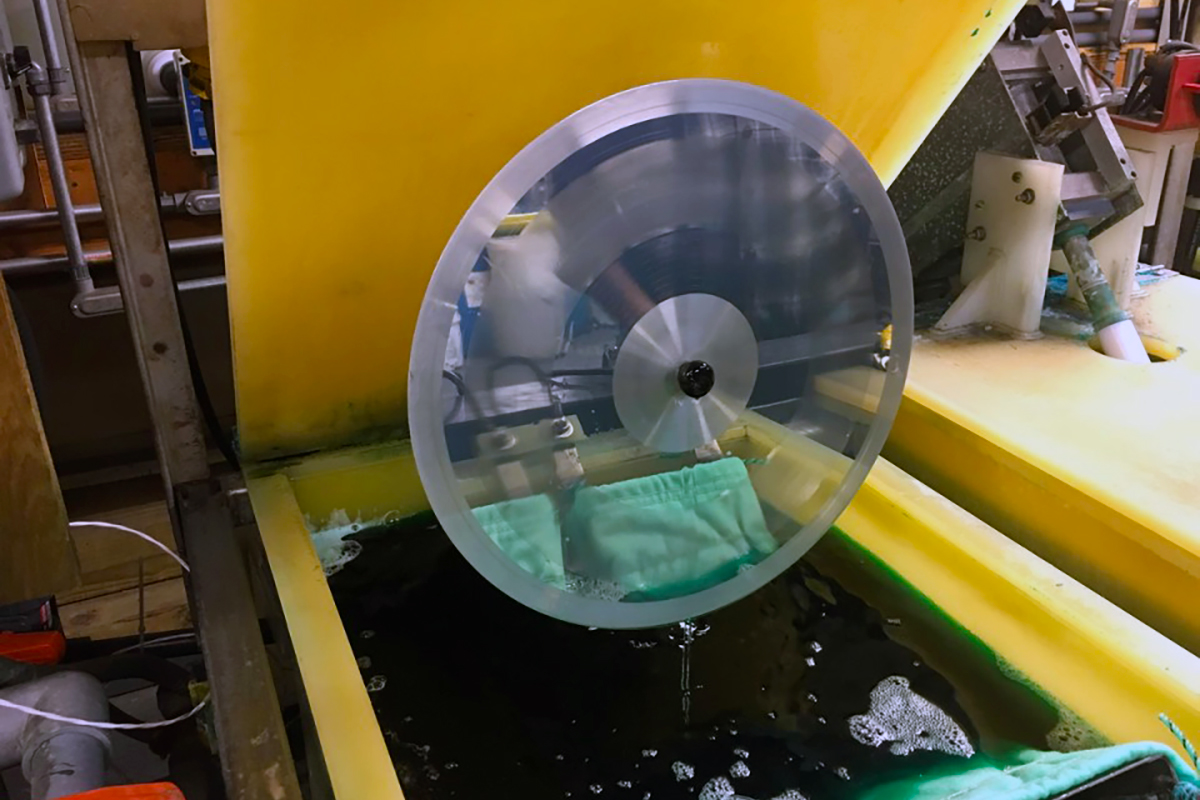

Nickel is used to make the master plates and stampers that vinyl records are pressed from. The process today is the same as used in the very early days of record pressing. Stampers are placed at the top and bottom of the press and the vinyl ‘puck’ is placed in between and squashed (pressed) under pressure to form the vinyl. To make the masters, there is a process called electroplating that takes place.

Electroplating is also referred to as the creation of the metal stampers. It’s a chemical process where a thin coat of silver is sprayed onto the lacquer master and occurs when the silver-coated lacquer is physically dipped into a nickel bath and ‘metallised’ or ‘plated’. Positively charged metal ions are attracted to the negatively charged silver-plated lacquer and attach themselves to the lacquer, forming a thin, but solid, plate attached to the lacquer.

When electroplating takes place, a decision must be made to use either 2-step or 3-step electroplating. 2 step electroplating can press around 1000 records, but 3 step plating can press over 50,000 records.

So, without the nickel process, records can't be made and with a shortage of nickel, the pressure increases on vinyl plants to find ways of recycling masters they hold or rationing what they have.

In terms of pricing, what we are seeing at the moment is a surcharge being added instead of a price increase. That means, when the price decreases, the surcharge will decrease and hopefully disappear going forward.

If you haven't ever seen the process of silvering and plating check out this video -

https://www.youtube.com/watch?v=MMs-nxM0VXU